Polyester Fiber Staple

Like other synthetic fibers, polyester fibers are produced via industrial processes and are ideal substitutes for natural fibers such as cotton due to their desirable properties. Manufactured by combining dimethyl terephthalate, monoethylene glycol, or terephthalic acid (a substitute for the raw material dimethyl terephthalate) with effective catalysts, polyester is treated with titanium dioxide to achieve a semi-dull appearance. Before packaging, the product is also submerged in a finishing solution (approximately 0.150%) for added stability.Product Identification

Production Process and Packaging

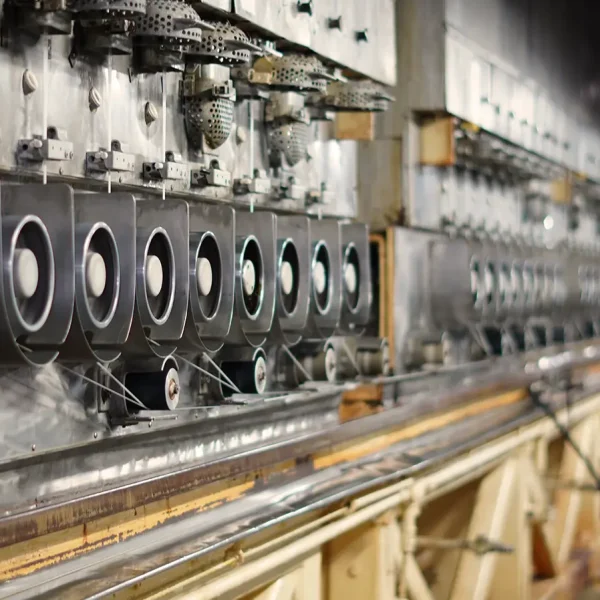

Polyester polymer is produced through an esterification process involving monoethylene glycol and dimethyl terephthalate. This chemical reaction, catalyzed and conducted under specific temperature and pressure conditions, takes place in three reactors within the Polymerizer Area. The resulting high-viscosity polymer is then conveyed via a screw pump to a 64-position spinning machine for melt spinning.

To refine the polymer chains, the material is filtered and streamlined through a series of packs, ensuring a uniform flow. Metering pumps deliver the polymer to spinnerettes, where it is extruded into superfine filaments. These filaments are rapidly cooled and solidified by a quenching air current, then collected in cylindrical containers known as ‘cans.’

To enhance the physical and mechanical properties of the fibers, they undergo a series of processes including spinning, drawing, and crimping, which aim to mimic the characteristics of natural fibers. The staple fibers are then dried, finished to improve processability, and inspected to meet laboratory standards. Finally, the fibers are cut to the desired length and baled for further processing.

To obtain expert guidance on product selection, price inquiries, and sales conditions, please utilize our contact form to get in touch with our support team.